|

|

01/14/2015 |

I started this series with a bunch of questions. I started this series with a bunch of questions.

I've got two goals here - the first is figure out if I can get an edge that is the equal to or better of the edges I get using oil or water stones. The next goal is to figure out what's the fastest way of getting there. Finally, and make that three or four goals, can diamonds be used on my carving tools and are they an improvement on what I am already using? The last goal and let's just say, amongst my many goals, is answering the question: are diamonds a good solution for sharpening kitchens knives and other things that I get regularly asked to sharpen?

My first task was selecting stones and coming up with some testing process. I picked 8" Dia-sharp steel stones and a non-skid mat. These are the most appropriate for the shop. Selecting the 10" stones - normally I like the extra length - I figured wasn't justified just for testing. For grits I picked Coarse, Fine, Extra-Fine, Medium Extra Fine, and Extra, Extra Fine.

I included the coarse stone because I had one open, but I didn't use it. I just didn't need it. The fine stone - 600 mesh was a credit card sized stone that we had left over from product photography. Both the medium extra fine and the extra-extra fine I wanted to try because DMT says you can get a finished edge right from these stones. The extra fine (1200 mesh) is where Paul Sellers finishes up so I thought that it would be a good mainstream benchmark.

I also used a plain strop and a treated strop. The latter I never use except for carving tools as the honing compound used to treat a strop is coarser than my finishing water stones, but I wanted to see if I needed any finishing stones at all. Remember of course that I am trying all the stones to test them - I doubt my final recommendations will include even half of these. The non-skid mat is awesome. I know that over time they get dirty and don't work as well but for my testing and a lot of other sharpening stuff I do the mat has saved a lot of time in clamping and setups. It doesn't work well for holding wood for carving because the tools get jabbed in the work and everything moves, but for sharpening, especially with these heavy steel diamond stones it's awesome. (For water stones I use a wet paper towel which works wonders too).

All the pictures were taken with my cheapo USB microscope. For this test I just used a typical carbon steel chisel. I am going to try a D2 mortise chisel later.

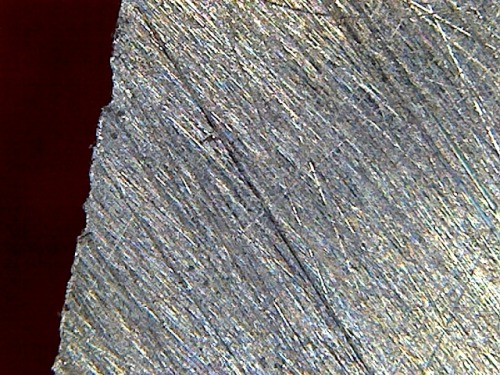

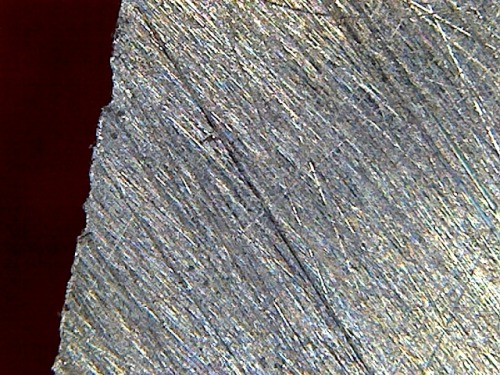

The chisel wasn't completely hollow ground. I started working the bevel and back using my fine grit (600 mesh) credit card stone. What is amazing was how fast the little credit card stone cut. In probably less than a minute I was ready to move on to a finer grit. What this tells me is that my preference for 8" stones -is just that - a preference. 6" stones or even 4" stones would work fine. (for wider blades just skew them on the stone). The major application of the larger stones really is for people using a honing guide and they need a larger surface to work efficiently. The picture i took was out of focus so lets just immediately go to the 1200 grit stone. Again, very, very fast cutting. The end result cleanly pared both maple and pine. You can honestly say - as some teachers do - that there is no need to go further. But a look under the microscope shows a ragged edge, and while the chisel works well - the action isn't as buttery or as effortless as I would like (first picture at the top).

So I stropped the edge on a green rouge covered piece of horse butt. A big improvement. The cutting edge was cleaner, although scratches remain. Paring end grain was easier.

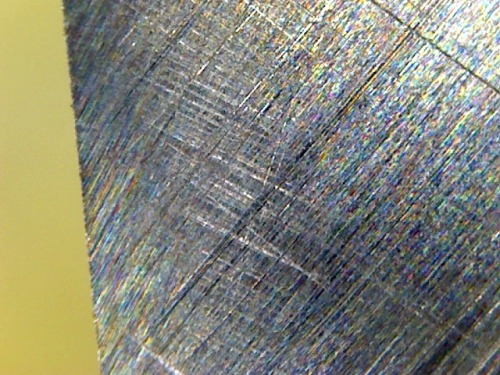

Then I tried the medium extra fine stone. Again, very fast cutting, but Ben says I can't recommend this stone because it's only available in the 8" size and it's much more expensive than everything else. The grit pattern is finer than previously, but my polished edge from the strop has disappeared. It pares about the same as the previous stropped edge.

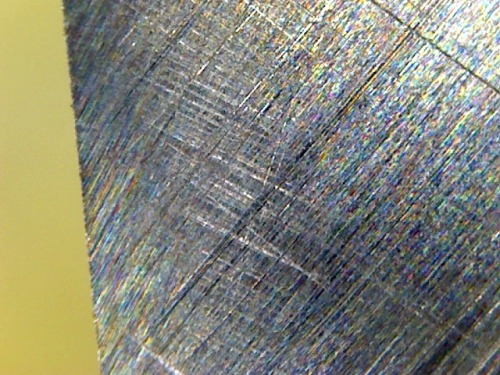

Then comes the extra-extra fine stone (picture on right). Very fast cutting, but I run into a problem. Because the diamonds cut so fast if I am not extremely careful the chisel can stutter a bit on the stone and then I get rounding at the tip. I think - although I haven't tested this - I'm working dry and working with water or oil would mitigate the stuttering and minimize this problem. The chisel does cut easier but the difference in quality of cut is minimal. Then comes the extra-extra fine stone (picture on right). Very fast cutting, but I run into a problem. Because the diamonds cut so fast if I am not extremely careful the chisel can stutter a bit on the stone and then I get rounding at the tip. I think - although I haven't tested this - I'm working dry and working with water or oil would mitigate the stuttering and minimize this problem. The chisel does cut easier but the difference in quality of cut is minimal.

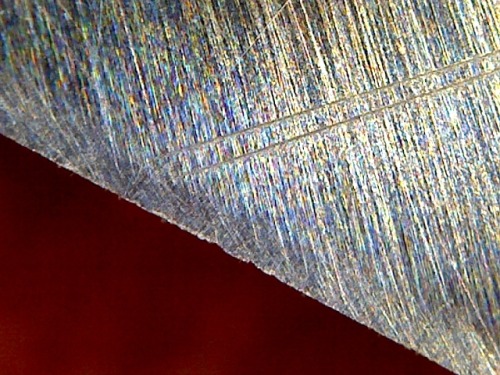

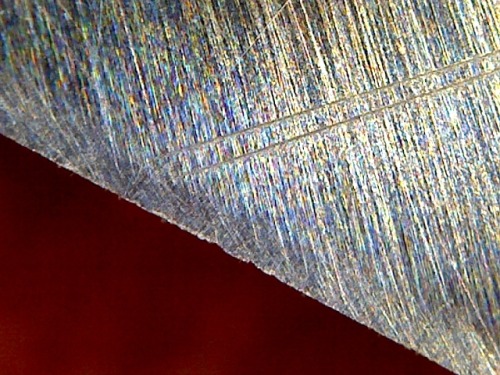

But I still have scratches. So out comes an 8K Norton waterstone (third picture) and to the naked eye a decent but not great polish quickly comes up. However under the microscope it is still pretty scratchy. The chisel works even better, with less effort. But I still have scratches. So out comes an 8K Norton waterstone (third picture) and to the naked eye a decent but not great polish quickly comes up. However under the microscope it is still pretty scratchy. The chisel works even better, with less effort.

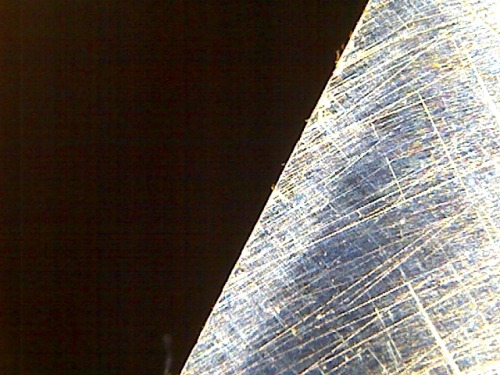

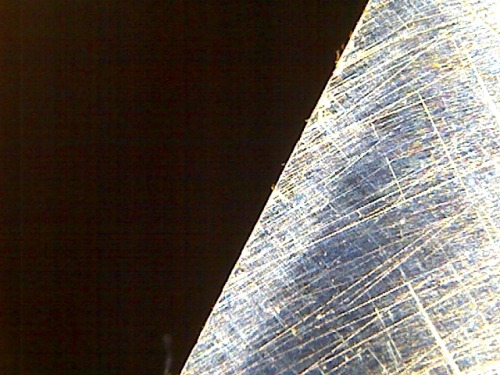

Finally (last picture) - A plain strop, no abrasive (as I have advocated for years). No dubbing of the edge, and the edge works easier still. The quality of the cut is marginally better than before.

My conclusion so far. Everything works. If you stop after the extra fine diamond stone you get a very useable edge. If you keep on going you get a better, easier to control, better surface leaving edge. With diamonds, getting rid of scratches is hard. In theory the absence of scratches give you a longer lasting edge, but I don't really have a controlled way of testing that.

This test wasn't about longevity, I can increase the longevity of the edge by using a microbevel ( 5 strokes of my finest stone at a very slightly raised angle) but that is a separate issue. For complete instructions on how I learned to sharpen visit my old web page here.

Where to go from here? Definitely using all the steps I used here is overkill, but I was just testing. The question now is what should be my final sequence? It's more than just grit and polish. It's time, convenience, I'm not to thrilled about dry sharpening, the dust is getting everywhere. Also, maybe following the extra extra fine with an Arkansas stone will be easier. I don't know. Also this is carbon steel. The next step is to repeat everything with a D2 chisel and maybe an exotic plane blade. Stay turned.

Click here for part three and my conclusions.

|

Join the conversation |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

I

I  Then comes the extra-extra fine stone (picture on right). Very fast cutting, but I run into a problem. Because the diamonds cut so fast if I am not extremely careful the chisel can stutter a bit on the stone and then I get rounding at the tip. I think - although I haven't tested this - I'm working dry and working with water or oil would mitigate the stuttering and minimize this problem. The chisel does cut easier but the difference in quality of cut is minimal.

Then comes the extra-extra fine stone (picture on right). Very fast cutting, but I run into a problem. Because the diamonds cut so fast if I am not extremely careful the chisel can stutter a bit on the stone and then I get rounding at the tip. I think - although I haven't tested this - I'm working dry and working with water or oil would mitigate the stuttering and minimize this problem. The chisel does cut easier but the difference in quality of cut is minimal.  But I still have scratches. So out comes an 8K Norton waterstone (third picture) and to the naked eye a decent but not great polish quickly comes up. However under the microscope it is still pretty scratchy. The chisel works even better, with less effort.

But I still have scratches. So out comes an 8K Norton waterstone (third picture) and to the naked eye a decent but not great polish quickly comes up. However under the microscope it is still pretty scratchy. The chisel works even better, with less effort.

"Initially, the diamond surface will seem aggressive in nature; the diamond sharpener will smooth after initial sharpening with no impact to long term performance."

Several years ago I purchased a full set of DMT stones and was appalled by the deep scratching they left in the steel. I was so disappointed that I actually did testing and took several pictures because I fully intended to return the stones and burn DMT a new one when suddenly the stones started to perform much better and deliver much smoother steel. I am still happily using that set of stones today.

This is one of your best technical articles to date, Joel.

Hollow grind to establish or change the primary angle or grind back a wide micro bevel.. Then, I most often go directly to the 1200 diamond (med/fine DuoSharp), then 8k diamond plate and finish off on a 15k Shapton Pro. IMO, a charged strop gives me the same edge, but has a higher risk of dubbing the edge, so I switched.

Diamonds and Shapton is lubricated with a spritz of water.

It's not a prefect system and my technique is far from perfect, but even with my mismatched set, I get good results with little messing around. I have a coarse plate as well but I use it primarily for flattening backs and flattening the water-stone.

Your article is really interesting (and timely) as I consider what pieces to remove or replace.

I have extra coarse and coarse stones - because I still like to rehab old beat-up plane blades and chisels. I like the new large stones because I do use a guide when having to completely re-establish a primary bevel on an old chipped Weatherly chisel or 100 y.o. Stanley No.8 blade. But I concede that the small stones are adequate for routine sharpening at the bench.

I too find that honing on the xxfine stone is a great working edge with no stropping to dub the final edge. (Black Arkansas is also a great final grit)

Great article, and I look forward to your final sharpening routine and recommendations.